-

Proforma invoice (0)

-

English

شرکت آنتی بیوتیک سازی ایران (ASICo)

Privately held company

CFIL43422

Overview

Trade Models: Manufacturer

Trade Models: Manufacturer

Industry or Business : Chemicals , Health & Medicine

Industry or Business : Chemicals , Health & Medicine

Business Location:

Iran

-

Tehran

Business Location:

Iran

-

Tehran

Total Employee: From 501 to 1000 people

Total Employee: From 501 to 1000 people

Establishment Year: 1995

Establishment Year: 1995

Website Address: www.asico.org

Website Address: www.asico.org

As the largest pharmaceutical complex in the province, it was established in 1374 on a land with an area of 160,000 square meters, of which 25,000 square meters have been allocated to the infrastructure of the factory buildings. This complex is located in a beautiful area near the Caspian Sea in the north of Iran.

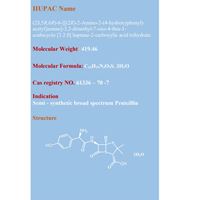

The company was put into operation in 1380 with the production of penicillin family products including 6-APA, amoxicillin and ampicillin. And then it continued its activity with the production of the active pharmaceutical ingredients of the cephalosporin family, including cephalexin and cefixime.

With the expansion of production lines, it entered other therapeutic groups since 2017 with the production of the active ingredient valsartan for the first time. It started in the country and currently, in addition to beta-lactam antibiotics in separate lines, other effective pharmaceutical substances are also produced in the general lines of the company. Industrial were selected and Antibiotics was included in the list of stock companies since 2019.

Iran Antibiotics has more than 200 experienced and knowledgeable personnel in the factory and office in Tehran, and with more than 20 years of experience in the production of active pharmaceutical ingredients, it is the largest producer of active ingredients of oral beta-lactam antibiotics. It is in the country.

ASICO's unique feature is being a leader in the field of biocatalytic product production. and the production and recycling of solvents is divided.

The company has 6 production lines which are:

Penicillin production line (products include fine and compact powder: Amoxi Cilin, ampicillin, 6-APA)

Cephalosporins production line (products including fine and compact powder: Cephalexin, Cefixime)

General production line (products of different treatment groups including: Azithromycin (Macrolide), Valsartan ( cardiovascular), quetiapine fumarate (nerve and mental), acyclovir (antiviral), sitagliptin phosphate (antidiabetes) (HVLV production line (products include: ticagrelor, linagliptin) chemical intermediates production line) The products include: Mica Ester, 7-AVCA, MBT, MBTS, etc.)

The recovery unit with a capacity of 5 tons per hour is one of the rare units in the chemical and pharmaceutical industries, which is used to recycle and produce solvents. The production of dimethoxymethane solvent is one of the main products of this unit. In order to achieve superior quality, all the company's processes are in accordance with GMP and WHO rules, and the quality assurance unit monitors and controls all production processes and stages. It is complete.

Important certificates and awards obtained:

Obtaining the GMP certificate for the production lines of penicillins, cephalosporins and general production line

Obtaining the certificate Environmental management system based on ISO 14001:2015, occupational health and safety management system based on ISO 45001:2018, quality management system based on ISO9001:2015, customer satisfaction management system and handling customer complaints based on ISO 10002:2018 and management system Knowledge based on ISO 30401:2018

Achieving the first rank and receiving the Simin statue in the fourth ranking period of Shasta subsidiaries

Received the certificate of Danesh Banyan Industrial Company

Received the certificate of two stars for excellence in human resources

Obtaining the certificate of reputation for the quality of food and medicine

Obtaining the title of industrial sample unit of Mazandaran province for 7 consecutive years from 2014 to now

Obtaining the title of sample working group of Mazandaran province for 7 consecutive years from 2014 to now

Selected unit in the food and drug industry of Mazandaran province

Improve the level of satisfaction of all stakeholders, commitment to maintaining health and maintaining specialist human capital, commitment to preventing environmental pollution and creating the necessary platforms to move towards organizational excellence from The main goals and policy of Iran Antibiotics Company. More

0

0 Review

...

Overview

Trade Models: Manufacturer

Trade Models: Manufacturer

Industry or Business : Chemicals , Health & Medicine

Industry or Business : Chemicals , Health & Medicine

Business Location:

Iran

-

Tehran

Business Location:

Iran

-

Tehran

Total Employee: From 501 to 1000 people

Total Employee: From 501 to 1000 people

Registration Date: 1995

Registration Date: 1995

Website Address: www.asico.org

Website Address: www.asico.org

As the largest pharmaceutical complex in the province, it was established in 1374 on a land with an area of 160,000 square meters, of which 25,000 square meters have been allocated to the infrastructure of the factory buildings. This complex is located in a beautiful area near the Caspian Sea in the north of Iran.

The company was put into operation in 1380 with the production of penicillin family products including 6-APA, amoxicillin and ampicillin. And then it continued its activity with the production of the active pharmaceutical ingredients of the cephalosporin family, including cephalexin and cefixime.

With the expansion of production lines, it entered other therapeutic groups since 2017 with the production of the active ingredient valsartan for the first time. It started in the country and currently, in addition to beta-lactam antibiotics in separate lines, other effective pharmaceutical substances are also produced in the general lines of the company. Industrial were selected and Antibiotics was included in the list of stock companies since 2019.

Iran Antibiotics has more than 200 experienced and knowledgeable personnel in the factory and office in Tehran, and with more than 20 years of experience in the production of active pharmaceutical ingredients, it is the largest producer of active ingredients of oral beta-lactam antibiotics. It is in the country.

ASICO's unique feature is being a leader in the field of biocatalytic product production. and the production and recycling of solvents is divided.

The company has 6 production lines which are:

Penicillin production line (products include fine and compact powder: Amoxi Cilin, ampicillin, 6-APA)

Cephalosporins production line (products including fine and compact powder: Cephalexin, Cefixime)

General production line (products of different treatment groups including: Azithromycin (Macrolide), Valsartan ( cardiovascular), quetiapine fumarate (nerve and mental), acyclovir (antiviral), sitagliptin phosphate (antidiabetes) (HVLV production line (products include: ticagrelor, linagliptin) chemical intermediates production line) The products include: Mica Ester, 7-AVCA, MBT, MBTS, etc.)

The recovery unit with a capacity of 5 tons per hour is one of the rare units in the chemical and pharmaceutical industries, which is used to recycle and produce solvents. The production of dimethoxymethane solvent is one of the main products of this unit. In order to achieve superior quality, all the company's processes are in accordance with GMP and WHO rules, and the quality assurance unit monitors and controls all production processes and stages. It is complete.

Important certificates and awards obtained:

Obtaining the GMP certificate for the production lines of penicillins, cephalosporins and general production line

Obtaining the certificate Environmental management system based on ISO 14001:2015, occupational health and safety management system based on ISO 45001:2018, quality management system based on ISO9001:2015, customer satisfaction management system and handling customer complaints based on ISO 10002:2018 and management system Knowledge based on ISO 30401:2018

Achieving the first rank and receiving the Simin statue in the fourth ranking period of Shasta subsidiaries

Received the certificate of Danesh Banyan Industrial Company

Received the certificate of two stars for excellence in human resources

Obtaining the certificate of reputation for the quality of food and medicine

Obtaining the title of industrial sample unit of Mazandaran province for 7 consecutive years from 2014 to now

Obtaining the title of sample working group of Mazandaran province for 7 consecutive years from 2014 to now

Selected unit in the food and drug industry of Mazandaran province

Improve the level of satisfaction of all stakeholders, commitment to maintaining health and maintaining specialist human capital, commitment to preventing environmental pollution and creating the necessary platforms to move towards organizational excellence from The main goals and policy of Iran Antibiotics Company.

Goods and Services

Office or company photo

company.photos.nophoto

Certificate and honors

Not added yet.

Production/Service website

کیلومتر 5 جاده خزرآباد(فرح آباد) - ساری - Mazandaran - Iran -

Overall Rating

Business supply chain network

details

شرکت آنتی بیوتیک سازی ایران (ASICo)

Start Date :

Expiration Date :

StartDate

ExpireDate