-

Proforma invoice (0)

-

English

- English

- پارسی

- 中国

- Russian

- العربية

- Spanish

- Deutsch

- اردو

- Türkçe

- Français

- Italy

- پشتو

IRANIAN BEARING COMPANY (IBC)

Overview

Trade Models: Trading Company, Manufacturer

Trade Models: Trading Company, Manufacturer

Industry or Business : Hardware, Tools & Mechanical Parts

Industry or Business : Hardware, Tools & Mechanical Parts

Business Location:

Iran

-

East Azerbaijan

Business Location:

Iran

-

East Azerbaijan

Total Employee: From 301 to 500 people

Total Employee: From 301 to 500 people

Establishment Year: 1969

Establishment Year: 1969

Website Address: www.ibct.ir

Website Address: www.ibct.ir

IRANIAN BEARING COMPANY (IBC) has been established in 30 October 1969 in partnership with the SKF Swedish Company. This company manufactures ball bearing and taper roller bearings based on specifications provided by the ISO (International Standard Organization). The company's factory, with an area of over 14 hectares, is located in the city of Tabriz producing more than 6.3 million ball-bearing and taper roller bearings and more than 12 million pieces of bearing balls and taper rollers in different sizes. This factory equipped with most advanced manufacturing techniques with the best quality characteristics and very strong and precise quality control system, and all its products and rotational precision of IBC bearings is in accordance with international standards.

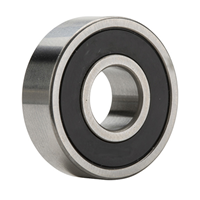

- Single-row deep groove ball bearings

- Taper roller bearings

- Steel balls

Applying and enforcing precise quality control methods, such as microscopic measurement, dimensional accuracy, surface roughness, noise and vibration measurements in 1800 rpm rotation, and metallography are among the tests have been performed in the IBC manufacturing process. IBC also manufactures special deep-groove ball bearings in normal tolerances for automobile manufacturing industry.

The use of precise and advanced measuring equipments for measuring and analysis of the outstanding characteristics of bearings are among the significant and main goals in quality assurance, which indicates high-level and available reliability offering very reliable products.

Also in 2007, this company designed bearings used in Peugeot Series gearbox and the Peugeot front and rear wheel axels, having double row angular contact ball bearing & HUB bearing Types, which was designed for the first time and will be produced in large scale in the second phase after the final approval.

To ensure the quality of the manufactured bearings, highly precise and advanced measuring equipments, as well as effective quality management system have been used. These include machines for measuring surface roughness test, level of Roundness, Rockwell hardness, and etc., which are used in the company's metrology and metallurgical laboratories.

IRANIAN BEARING COMPANY Laboratory is ready to provide testing services for bearings used in different industries by establishing quality management system based on ISO/IEC 17025:2005 Quality Management System Standard.

In line with the design and development of the company?s manufacturing activities, the company manager has attempted to increase the number of company products, both qualitatively and quantitively, and in this regard, he aims to increase its annual production from 6.3 million to 11 million per year. For this, manufacturing new bearings for newly manufactured automobiles is the first priority. In addition to above products and considering its high technical power, the company puts providing of all bearings required in the country's industry as its agenda, announcing his preparation as a technical arm of the country's industry in this area.

Overview

Trade Models: Trading Company, Manufacturer

Trade Models: Trading Company, Manufacturer

Industry or Business : Hardware, Tools & Mechanical Parts

Industry or Business : Hardware, Tools & Mechanical Parts

Business Location:

Iran

-

East Azerbaijan

Business Location:

Iran

-

East Azerbaijan

Total Employee: From 301 to 500 people

Total Employee: From 301 to 500 people

Registration Date: 1969

Registration Date: 1969

Website Address: www.ibct.ir

Website Address: www.ibct.ir

IRANIAN BEARING COMPANY (IBC) has been established in 30 October 1969 in partnership with the SKF Swedish Company. This company manufactures ball bearing and taper roller bearings based on specifications provided by the ISO (International Standard Organization). The company's factory, with an area of over 14 hectares, is located in the city of Tabriz producing more than 6.3 million ball-bearing and taper roller bearings and more than 12 million pieces of bearing balls and taper rollers in different sizes. This factory equipped with most advanced manufacturing techniques with the best quality characteristics and very strong and precise quality control system, and all its products and rotational precision of IBC bearings is in accordance with international standards.

- Single-row deep groove ball bearings

- Taper roller bearings

- Steel balls

Applying and enforcing precise quality control methods, such as microscopic measurement, dimensional accuracy, surface roughness, noise and vibration measurements in 1800 rpm rotation, and metallography are among the tests have been performed in the IBC manufacturing process. IBC also manufactures special deep-groove ball bearings in normal tolerances for automobile manufacturing industry.

The use of precise and advanced measuring equipments for measuring and analysis of the outstanding characteristics of bearings are among the significant and main goals in quality assurance, which indicates high-level and available reliability offering very reliable products.

Also in 2007, this company designed bearings used in Peugeot Series gearbox and the Peugeot front and rear wheel axels, having double row angular contact ball bearing & HUB bearing Types, which was designed for the first time and will be produced in large scale in the second phase after the final approval.

To ensure the quality of the manufactured bearings, highly precise and advanced measuring equipments, as well as effective quality management system have been used. These include machines for measuring surface roughness test, level of Roundness, Rockwell hardness, and etc., which are used in the company's metrology and metallurgical laboratories.

IRANIAN BEARING COMPANY Laboratory is ready to provide testing services for bearings used in different industries by establishing quality management system based on ISO/IEC 17025:2005 Quality Management System Standard.

In line with the design and development of the company?s manufacturing activities, the company manager has attempted to increase the number of company products, both qualitatively and quantitively, and in this regard, he aims to increase its annual production from 6.3 million to 11 million per year. For this, manufacturing new bearings for newly manufactured automobiles is the first priority. In addition to above products and considering its high technical power, the company puts providing of all bearings required in the country's industry as its agenda, announcing his preparation as a technical arm of the country's industry in this area.

Goods and Services

Featured Products

Deep Groove Ball Bearings

Office or company photo

Business employees have not posted any photos yet.

Certificate and honors

Not added yet.

Production/Service website

Iranian Bearing Company, West Industrial Zone - Tabriz - East Azerbaijan - Iran -

- Phone Number : +984134451031

Overall Rating

Business supply chain network